Dry-well calibrators play a crucial role in ensuring accurate temperature measurements across various industries. To further enhance their effectiveness, it's essential to delve into specific aspects of their operation and performance. One critical subset worth exploring is the impact of block loading errors on calibration accuracy.

Block Loading Errors:

Block loading errors arise due to shifts in temperature gradients caused by changes in heat loss or gain when additional thermometers are inserted into the block. This phenomenon becomes particularly noticeable when employing the direct calibration mode, where the dry-well's control sensor is calibrated against a single reference thermometer within the block.

Mitigating Block Loading Errors:

To minimize block loading errors, it's advisable to use a reference thermometer aligned with the Unit Under Test (UUT) during calibration. This technique cancels out much of the additional uniformity error induced by loading additional thermometers into the sleeve.

Measurement and Analysis:

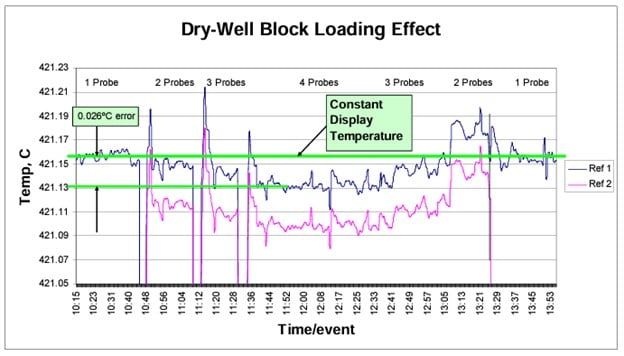

Block loading errors can be quantified by inserting a monitoring thermometer into a well of the sleeve and recording its temperature over time. As additional thermometers are added incrementally, the temperature shifts observed in both the dry-well's display and the monitoring thermometer can be noted. Reversing the process by removing inactive thermometers ensures that the original temperature is restored, allowing for a comprehensive assessment of loading effects.

Example:

Figure below illustrates a typical test scenario for measuring block loading errors. By establishing the block's temperature using a reference probe and incrementally adding thermometers to mimic thermal load, any deviations from the initial temperature can be observed. This data enables the determination of typical block loading errors, which can then be factored into the uncertainty budget for calibration processes.

Conclusion:

Addressing block loading errors is crucial for maintaining the accuracy and reliability of temperature calibrations performed using dry-well calibrators. By understanding the underlying mechanisms and employing appropriate measurement techniques, users can effectively mitigate these errors and ensure precise temperature measurements across various applications.